Highlight:

CuNi19 Enameled Copper Nickel Alloy Wire

, CuNi14 Enameled Copper Nickel Alloy Wire

, CuNi10 Enameled Copper Nickel Alloy Wire

Enameled Copper Nickel Alloy Wire CuNi1/CuNi2/CuNi5/CuNi8/CuNi10/CuNi14/CuNi19 CuNi23 CuNi30 CuNi34 CuNi44

Enameled Copper Nickel Alloy Wire (CuNi1/CuNi2/CuNi5/CuNi8/CuNi10/CuNi14/CuNi19, CuNi23, CuNi30, CuNi34, CuNi44)

1) General Description:

Constantan (CuNi 44 Alloy): A Copper-Nickel alloy. High specific resistance alloy used in wire-wound precision resistors, potentiometers, volume control devices, winding heavy-duty industrial rheostats and electric motor resistances.

Also used as thermocouple alloy with Copper (Type T), Iron (Type J), and Ni-Cr (Type E). It is available with grade wires and extension wires.

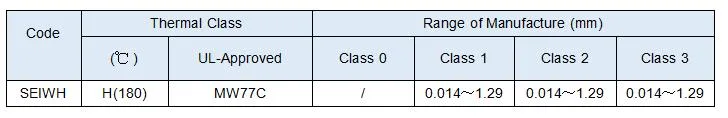

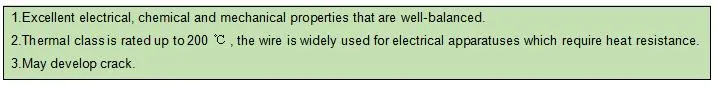

This wire is the same as conventional polyesterimide enamelled copper wire except solderability has been added to eliminate terminal preparation work.

Applicable standard:JCS 2394,NEMA MW77C,IEC60317-23

Applications:Small motors, small transformers.

Features

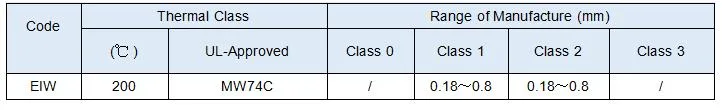

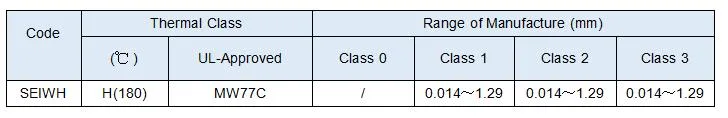

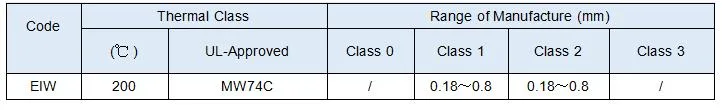

Thermal class and range of manufacture

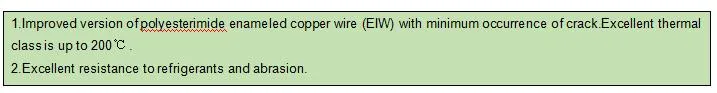

EIW Polyesterimide Enamelled Copper Wire

This wire is enameled with insulating varnish,main ingredient is isocyanuric polyesterimide resin.

Applicable standard:JIS C 3202,NEMA MW74C.

Applications:Heat-resistant general-purpose motors, automotive parts, transformers.

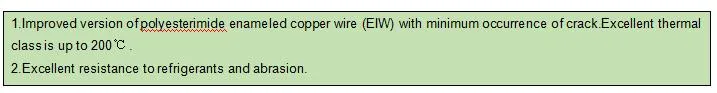

Features

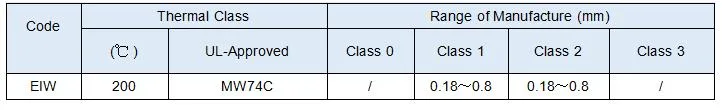

Thermal class and range of manufacture

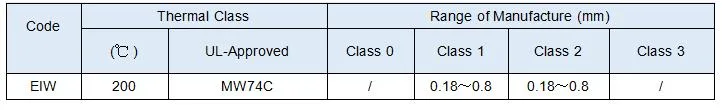

EI/AIW Polyesterimide overcoated with Polyamideimide Enamelled Copper Wire

This wire has double layers of enamelled coatings-polyamideimide for upper layer and polyesterimide for lower layer.

JCS 2392 NEMA MW35C,MW73C,IEC60317-13.

Thermal class and range of manufacture

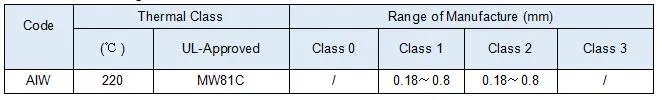

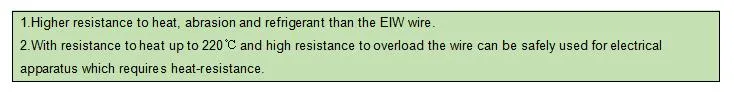

AIW Polyamideimide Enamelled Copper wire

This wire is coated with an insulating varnish and main ingredient is polyamideimide resin.

Applicable standard:JCS 2334,NEMA MW81C,IEC60317-57.

Applications:Heat-resistant motors, motors for electric tools. Heatresistant dry type transformers, lifting magnet coils.

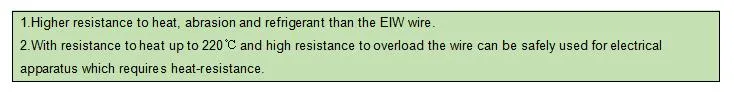

Features

Thermal class and range of manufacture

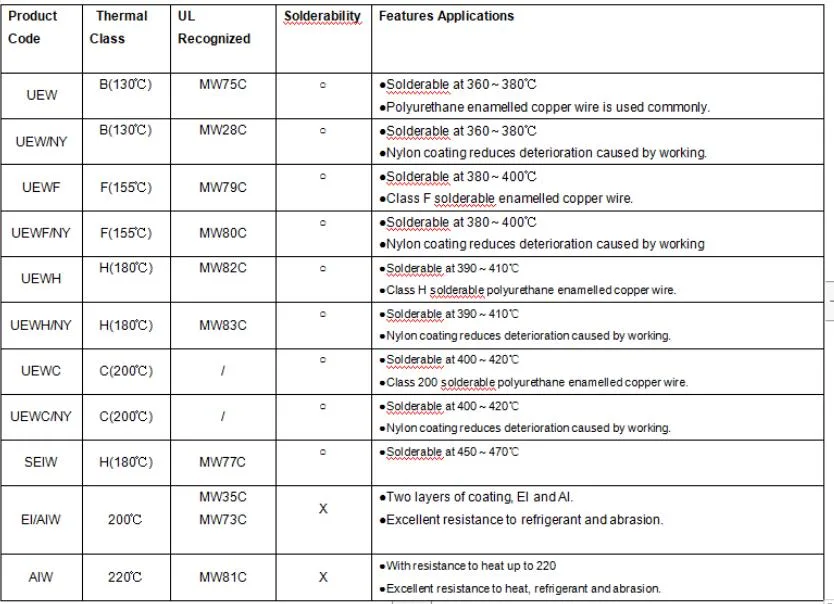

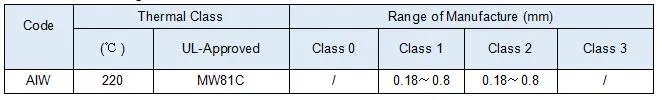

Comparative Table - General Magnet Wires

4) Usage: Resistance heating elements; Material in metallurgy; Household appliances; Mechanical manufacturing and other industries.

5)We can also supply other products by processing on your order: Stranded wire, twisted wire, coiled wire, wave-shaped wires and different kinds of standard or non-standard electrical heating element.

Shanghai TANKII ALLOY MATERIAL Co., Ltd.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!