Highlight:

15kg Arc Spray Wire

, ERCuAl-A1 Arc Spray Wire

, 1.6mm Arc Spray Wire

Prime Quality Arc Spray Wire 1.6mm Al Bronze ERCuAl-A1 Wire 15kg Per Spool For Thermal Spray Coating Process

Prime Quality Arc Spray Wire 1.6mm Al Bronze Wire 15kg Per Spool For Thermal Spray Coating Process

What's thermal spray wire?

Thermal spray wire is a type of wire used in the thermal spray coating process.

Thermal spraying is a surface enhancement technique where a material, in the form of wire or powder, is melted and propelled onto a substrate to create a coating.

The wire is typically made of a material such as metal or alloy, and it is fed into a thermal spray gun where it is heated and propelled onto the surface to be coated.

The molten particles solidify upon impact, forming a coating that provides various benefits such as corrosion resistance, wear resistance, and thermal insulation.

Thermal spray wire is available in different compositions to suit specific coating requirements.

Product Overview:

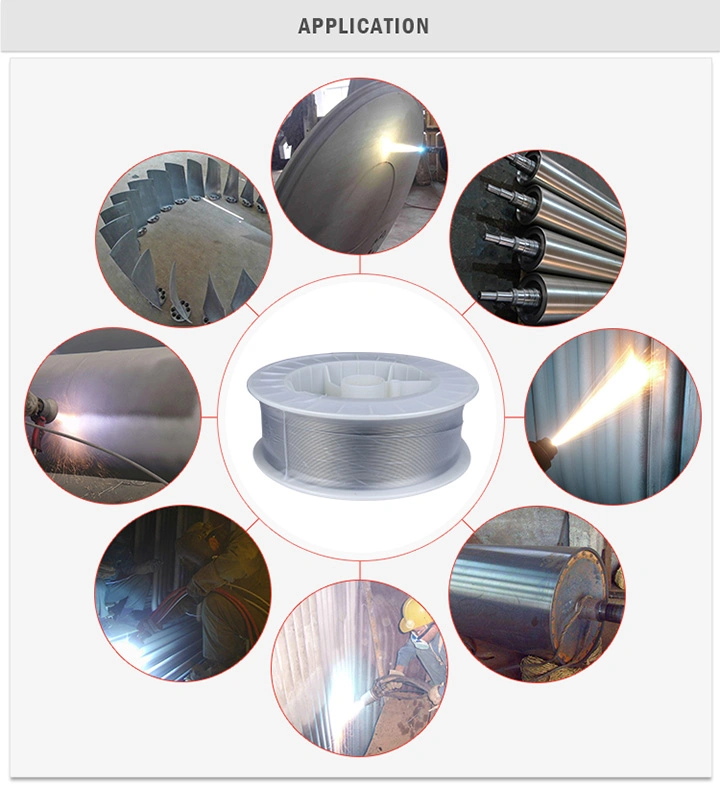

Al Bronze spray wire refers to a type of thermal spray wire that is composed of aluminum and bronze alloy. It is specifically designed for use in the thermal spray coating process. The Al Bronze spray wire is fed into a thermal spray gun, where it is heated and propelled onto the surface to be coated. Upon impact, the molten particles solidify, forming a coating that exhibits excellent wear resistance, corrosion resistance, and high strength. The aluminum in the alloy provides good bonding properties, while the bronze enhances the mechanical properties of the coating.

Al Bronze spray wire is commonly used in applications where high wear resistance and durability are required, such as in the automotive, aerospace, and marine industries.

Al Bronze spray wire

Chemical composition of thermal spray wire (wt%):

| Chemical composition(%) |

| Standard |

No. |

Grade |

Cu |

Al |

Fe |

Mn |

Ni |

P |

Pb |

Si |

Sn |

Zn |

Other |

| ISO24373 |

Cu6100 |

CuAl7 |

bal. |

6.0-8.5 |

- |

0.5 |

- |

- |

0.02 |

0.2 |

- |

0.2 |

0.4 |

| GB/T9460 |

SCu6100 |

CuAl7 |

bal. |

6.0-8.5 |

- |

max 0.5 |

- |

- |

- |

max 0.1 |

- |

max 0.2 |

max 0.5 |

| GB/T9460 |

SCu6100A |

CuAl8 |

bal. |

7.0-9.0 |

max 0.5 |

max 0.5 |

max 0.5 |

- |

max 0.02 |

max 0.2 |

max 0.1 |

max 0.2 |

max 0.2 |

| BS EN14640 |

Cu6100 |

CuAl8 |

bal. |

6.0-9.5 |

0.5 |

0.5 |

0.8 |

- |

0.02 |

0.2 |

- |

0.2 |

0.4 |

| AWS A5.7 |

C61000 |

ERCuAl-A1 |

bal. |

6.0-8.5 |

- |

0.5 |

- |

- |

0.02 |

0.1 |

- |

0.2 |

0.5 |

| DIN 1733 |

2.0921 |

SG-CuAl8 |

bal. |

7.5-9.5 |

max 0.5 |

max 1.0 |

max 0.8 |

- |

max 0.02 |

max 0.2 |

- |

max 0.2 |

max 0.4 |

Our Services

1) We can provide a free sample for testing.

2) Customized lable, packing, OEM service

3) Mill test certificate will be provided after production, If it is necessary.

4) Good packing methods to keep goods no damage during delivery

5) We are cooperation with many famous forwarder, will try our best to choose the safety, convenience, quick, and cheap mode of transportation for our customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!